The New | Type-3 Wind Plant command in the Main Window lets you add a new type-3 wind plant to a bus. The type-3 wind plant model is based on a phasor-domain model developed by EPRI, and by EPRI-funded research at Polytechnique Montreal. OneLiner’s type-3 wind plant model has been benchmarked against Polytechnique Montreal’s model. More information is available in the IEEE Technical Report PES-TR78 (see reference below).

A unique feature of a type-3 wind generator is the crowbarred state in which the rotor winding is disconnected from the back-to-back converter that normally provides the rotor-winding current, and the rotor winding is then short circuited electronically with a very small resistance. This is done primarily to protect the power electronics in the back-to-back converter in the event of a close-in fault.

When the generator is crowbarred, it effectively becomes a conventional induction generator. Typically, a fault near the terminal of a (MW-sized) crowbarred type-3 wind generator will cause the generator to inject 5 times the full load current into the utility network.

It is important to emphasize that the crowbarred state is initiated by transients that cannot be replicated by a phasor-domain short circuit program. For that reason, we provide a check box labeled “crowbarred” in the info dialog box of a type-3 wind plant, so that you can initiate the crowbarred state manually. Once crowbarred, OneLiner draw the type-3 wind plant symbol with a black background. See pictures below.

Crowbarred Under automatic control. Not Crowbarred

When a type-3 wind plant is under automatic control (i.e., not crowbarred), the current output is usually limited to 1.1 to 1.3 times the full load current. During an unbalanced fault, a type-3 wind plant will inject both positive- and negative-sequence currents into the network. No zero-sequence is injected because (a) type-3 wind generators are almost always connected line-to-line, and (b) the unit wye-delta transformer is connected with the delta winding on the collection-network side – block any zero-sequence current.

The reason we call this model a “wind plant”, instead of a wind turbine or a wind generator, is to encourage you to aggregate your machines as much as possible. Studies of type-1 wind machines have showed that the simulation results are largely unaffected by aggregating the machines. Also, aggregation will speed up the simulation and eliminated unwanted numeric oscillation between clusters of closely spaced wind turbines during the iterative solution.

The type-3 wind plant object is modeled both in short-circuit and in power-flow simulations (if you have a license for the power flow program). Iterations are required due to the general non-linear nature of the device. To simulation faults with type-3 wind plants, you must turn on the “Simulate type-3 wind plant” option in the Fault | Options dialog box.

Also, the prefault voltage option must be set to “From a linear network solution” or “From a power flow solution”. Type-3 wind plants are not modeled in OneLiner v15 if the prefault voltage is set to “Assumed flat”.

TO ADD A NEW TYPE-3 WIND PLANT FROM THE DEVICE PALETTE:

1a. Click on the New Type-3 Wind

Plant button  on the Device Palette.

The cursor will become a cross with a type-3 wind plant symbol attached to

it.

on the Device Palette.

The cursor will become a cross with a type-3 wind plant symbol attached to

it.

2a. Click on the one-line where you want to place the new wind plant.

Note: You can click on an existing bus to place the new wind plant on the bus. The bus cannot have any one of the following object already: a type-3 wind plant, a generator (with or without current limit), a voltage-controlled current source, or a converter-interfaced resource.

TO ADD A NEW TYPE-3 WIND PLANT TO A BUS USING MENU COMMAND:

1b. Select the bus.

Click the left mouse button once on the bus to which you want to add a type-3 wind plant.

The bus symbol will turn dotted red when selected.

2b. Select the Network | New | Type-3 Wind Plant command.

Note: This menu item is dimmed and cannot be activated if the bus you selected already has a type-3 wind plant, a generator (with or without current limit), a voltage-controlled current source, or a converter-interfaced resource.

A dialog box will appear asking for the type-3 wind plant data.

3. Specify the number of units in this plant.

The term “unit” refer to a type-3 wind generator.

4. Specify the unit MVA rating.

5. Specify the unit rated MW.

The program users this value, in conjunction with the parameter “slip at rated kW” (in the Advanced Settings dialog box) to calibrate the torque-versus-slip characteristics of the wind turbine blades.

6. Specify the unit MW generation.

If the prefault voltage option is set to “From a power flow”, enter the real power the wind plant is generating MWs before the fault. This value must be positive or zero.

If the prefault voltage option is “From a linear network solution”, we suggest you enter the value of 0 if there are no loads in the network. This will make it consistent with the classical treatment of conventional synchronous generators in short circuit programs. See Appendix K for a discussion of this topic.

7. Rotor side limit.

Output current limit, in per-unit, when the wind plant is under automatic control (i.e., not crowbarred).

8. Grid side limit.

Limit on the amount of power that is fed back from the stator winding to the back-to-back dc converters, which energizes the rotor winding. We suggest you leave this value as is.

9. Crowbarred

Mark this checkbox to simulate the crowbarred condition.

10. FLC

Press this button to see the full-load current of the type-3 wind plant, in amperes.

Click on the … button near the upper right corner of the text area below the Memo field to open the Supplemental Object Properties dialog box with a data grid to enter data for the following data fields:

11. Tags: Enter list of tag strings separated by semicolon. The tags are for organizing objects that are related for some purpose. Please see documentation for Network | Apply Tag for more information.

12. In/Out of service date: Click on the … button and enter the desired dates. See the Details and Techniques section “In/Out of service and tags” for more information.

13. User-defined fields: These are custom data fields that are defined by the user. Please see documentation for File | Preferences for information about how to specify the template for these data fields.

Advanced Settings

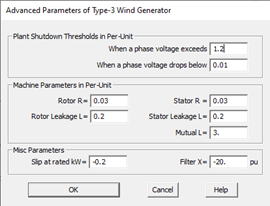

Press the “Advanced Settings” button to bring up this dialog box.

1. Terminal voltage limits.

The wind plant will shut down if a phase voltage exceeds the upper limit, or it goes below the lower limit. The lower limit can be as low as 0.0 per-unit. These limits do not apply when the wind plant is crowbarred.

Note: When entering the terminal-voltage limits for wind, solar and similar devices, we advise users to consult IEEE Standard 2800 and other relevant standards on voltage ride-through parameters. If you enter a value of zero for the low-voltage shutdown, please keep in mind that the unit can output current for a very brief period before it shuts down.

2. Induction machine parameters.

Electric parameters of the induction machine. There are five of them. See any textbook for explanation of these parameters.

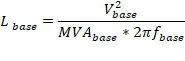

Note: The inductance per-unit base for stator, rotor, and mutual inductance parameters input in this model must be computed using the nominal grid frequency as:

Where:

Machine three-phase rating,

MVA

Machine three-phase rating,

MVA

Machine

line-to-line voltage rating, kV

Machine

line-to-line voltage rating, kV

Nominal

grid frequency, Hz

Nominal

grid frequency, Hz

3. Slip at rated kW.

See explanation above for the parameter unit rated MW. A minus slip means the wind turbine blades is slightly faster than the synchronous speed when the wind turbine generates the rated kW.

4. Filter X.

There are two harmonic filters within the generator. One filter is tuned to the first harmonics of the switching frequency of the VSC converter (typically in the range of 2 to 5 kHz). The second filter is tuned to the second harmonics. The value of x is the combined reactance of the two filters at the power frequency.

5. Press OK to close the Advanced Parameters dialog box.

Press the OK button in the main info dialog box when done. A type-3 wind plant will be added to the bus.

Reference: IEEE Power & Energy Society Technical Report PES-TR78 “Modification of Commercial Fault Calculation Programs for Wind Generators” June 2020.

Main Window

NETWORK MENU